Aporators, sometimes referred to as cooling units, chilling units, or freezing units, are usually placed in the upper food compartment and can also be expanded to cover the entire top of the cabinet and some even have their doors. Evaporators absorb heat from inside the room faster than the heat that enters through walls, from food, and other sources. Because heat always flows from warmer to cooler objects, heat from food and liquid in the cupboard will flow to the evaporator. So, the evaporator serves to reduce the temperature of food and stored fluids.

Evaporators are maintained at temperatures cooler than cooled rooms so they can absorb heat. This causes more cold air to fall and forces hot air to rise. This action gives rise to air movement. Because of that heat is carried to by natural air circulation, using convection. This circulation can also be strengthened by a fan.

The condensing unit is composed of a compressor, an electric motor for the compressor, a ground condenser to support the component, and a convection unit is forced to have a condenser fan driven by a separate motor. In a hermetically sealed system, the motor is connected to the compressor and both are closed in a steel dome with fixed oil filling.

Two tubes are connected to the evaporator and usually enter the cabinet room through a hole located in the back wall. A tube as a suction line (suction line) flows the coolant vapor from the evaporator to the compressor. The other pipe is a liquid channel that flows the coolant from the condenser to the evaporator. Cold gas inhaled cools the hot refrigerant liquid before the evaporator, thereby increasing system efficiency.

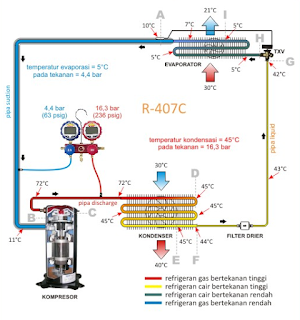

The end of the capillary pipe connected to the mouth of the condenser outlet is high pressure. If you look back at the channel toward the cołnpresor, you will see that the high pressure on the condenser, the compressor drain, and to the drain pole from the compressor pump to the capillary pipe are called high sides because they are under high pressure,

The inside of the evaporator is low pressure because steam is sucked out by the pump. This low pressure is also found in the suction line (suction line) in the condenser hood (condenser dome) and up to the compressor pump intake pole. The part of the system that is between the mouth of the capillary pipe and the pump intake valve, in a path through the evaporator is called the Iow side because it is under low pressure.

On the high pressure side is called head pressure and on the low pressure side is called suction pressure or back pressure. Obtained liquid and gas in low pressure as well as in the high pressure section. So, it is not true to say that one side only contains gas or liquid. But what distinguishes the two parts, not the problem of gas or liquid, but the pressure. Capillary pipes have high pressure at one end and low pressure at the other end when the compressor is operating. The difference in pressure and diameter in the pipe determines the speed of the coolant flow from high pressure and low pressure.

Capillary tubes also serve “emptying the load” when the high pressure part and when the compressor is not working. thus making the pressure between the high pressure and low pressure parts balanced. This facilitates the start of the compressor motor because both parts suck and dispose with the same pressure, so that smaller coupling of motion (star coupling) is required. Phase split type compressor motors are easier to use than using capacitors which are more complicated and have higher initial motion coupling characteristics. Therefore, technicians must have detailed knowledge of the components of the refrigerator system.